Worksheets on conversion of measurements: Grade 5 Measurement Worksheets | K5 Learning

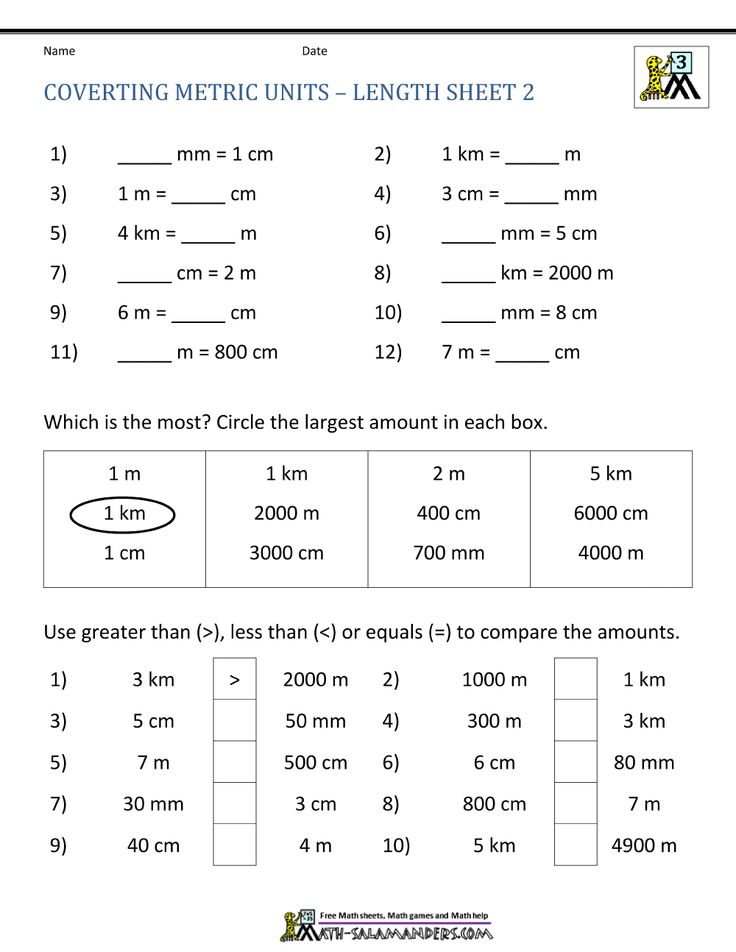

Posted onConverting Units of Length Worksheets

When we convert units of length we start by determining the conversion number. Once we have found that value, it becomes a simple multiplication exercise. Often these values are given to students, but the most common metric values of length are based off of meter. This pivots easily into millimeters, centimeters, and kilometers. In U.S. Measurement system, we base everything off of the inch. This grows to feet, yards, and miles. The common conversion between the systems is that one inch is the equivalent of two and one-half centimeters.

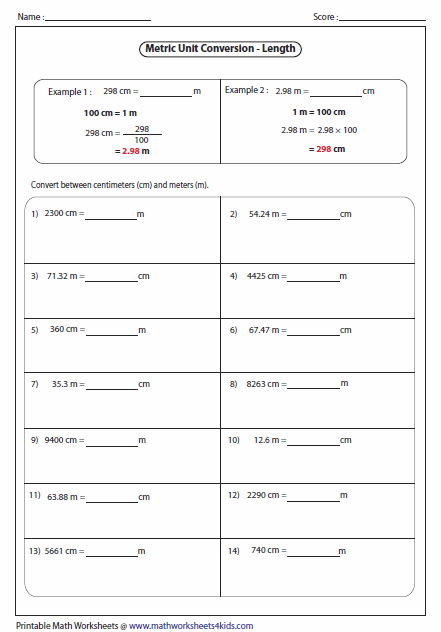

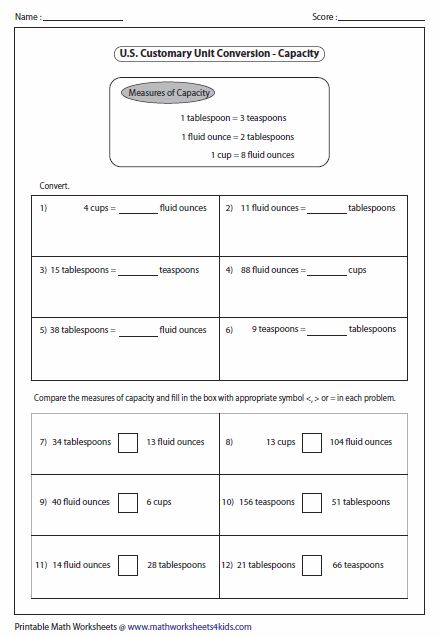

These worksheets explain how to convert between different measurements of length. Questions may use either Imperial or Metric units. Instructors may decide if calculators are allowed.

Get Free Worksheets In Your Inbox!

Click the buttons to print each worksheet and answer key.

This worksheet explains how to convert between different measurements of length. A sample problem is solved, and two practice problems are provided.

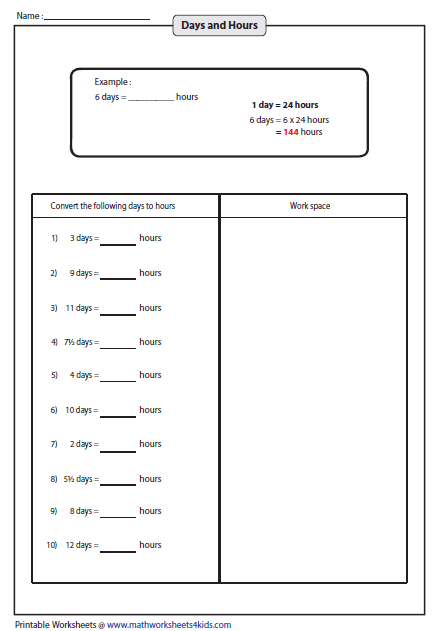

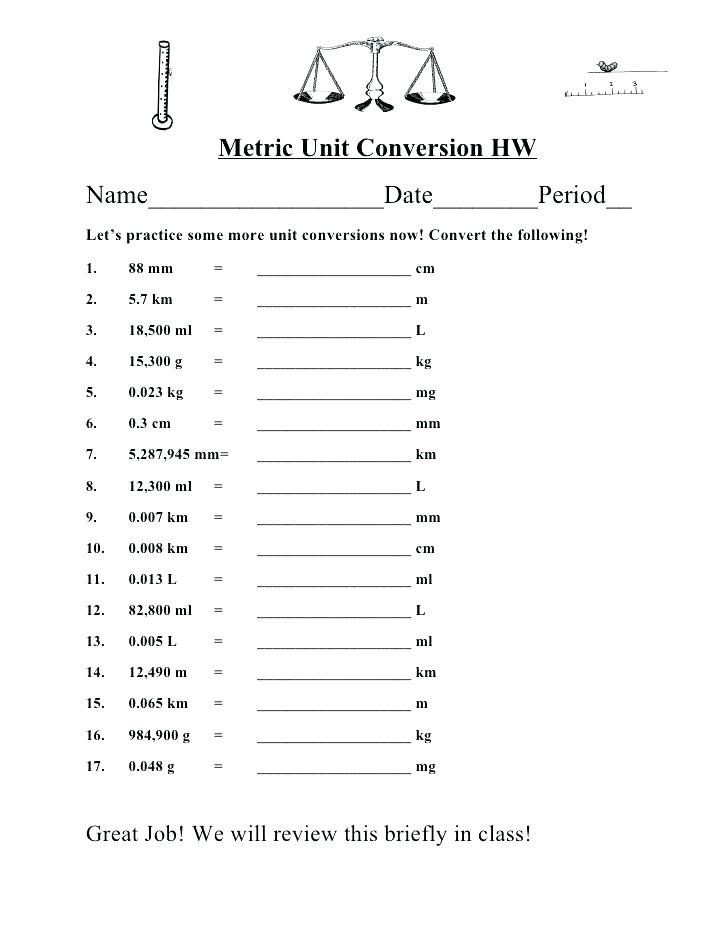

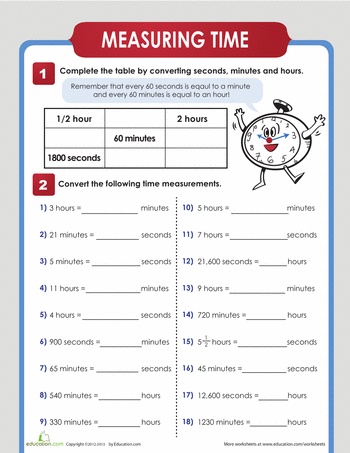

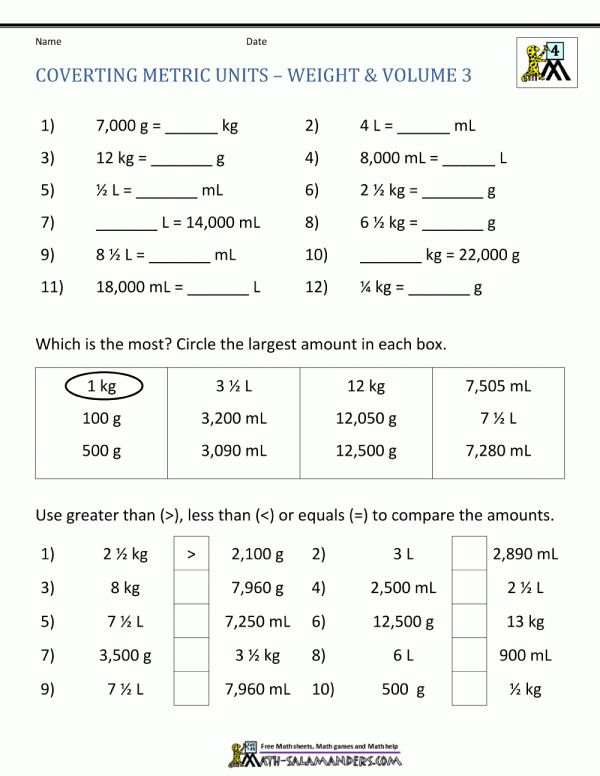

Students will convert between length, capacity, and mass. Ten problems are provided.

Students will practice converting between different measurements of length. Ten problems are provided.

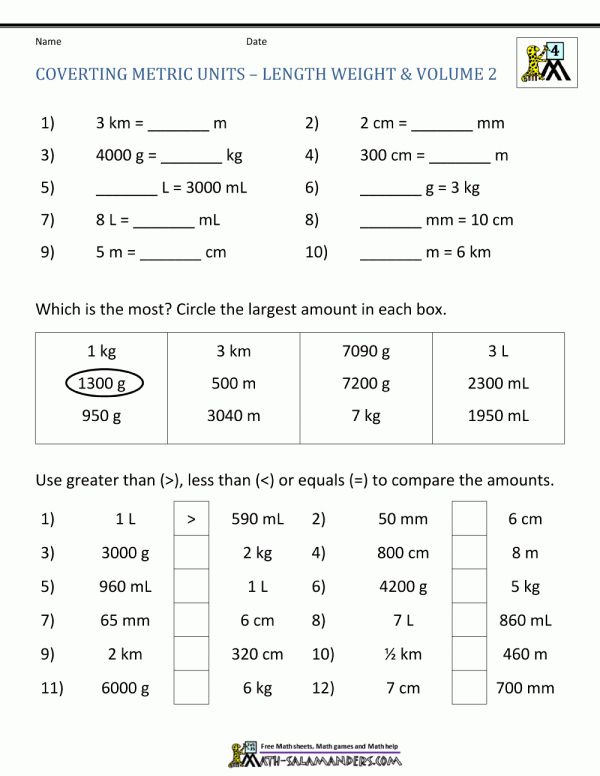

The concept of how to convert between different measures of length, mass, and capacity is reviewed. A sample problem is solved. Six practice problems are provided.

Students will demonstrate their proficiency with this quiz. Ten problems are provided.

Students will convert between different measures of all three units we have been working with. Three problems are provided, and space is included for students to copy the correct answer when given.

Convert 3 ft into inches.

When we divide 27 by 12 (i.e. 27 ÷ 12), we get 2 as quotient and 3 as remainder.

The quotient shows the part of the inches that are fully converted to feet and the

remainder shows the part that are not converted to feet.

Given either feet or inches, students will convert to the other unit of measurement. Ten problems are provided.

Convert the following measures into feet.

Students will solve problems by converting between feet and inches. Eight problems are provided.

Students will practice these skills some more. Three problems are provided.

Given one unit of length, students will convert to another unit of length. Ten problems are provided.

Students will practice converting between units of length. Ten questions are provided.

Students will be working more with these skills. Eight problems are provided.

What are Common Units of Length?

We know that there are different types of birds alive in the world today. Sparrows, crows, eagles, kiwis, and many more. But they are all part of the bird group in the animal kingdom because they follow some basic features needed to be a part of the bird’s group.

Similar to that, in math, we use a system of measurement called the metric system. The metric system helps us in identifying the units for measuring quantities such as weight, mass, length. Do you know what length is? Let us help!

In the simplest words, the length of an object is the measurement of the extent of the object from one end to the other. According to the metric system, the most common units of measurement for length are millimeter, centimeter, meter and kilometer.

The smallest unit for the measurement of length is known as millimeter. A millimeter is used to measure something very small such as a seed. It is abbreviated as mm.

Next to mm, comes centimeter. There are 10 mms in a centimeter. It is abbreviated as cm.

The next unit for the measurement of length is meter. One meter is much longer than a cm and is used to measure longer distances or bigger objects such as pools or rooms. Meter is abbreviated as m.

The biggest unit for the measurement of length is known as kilometer.

Customary and Metric

These conversion worksheets have problems with various levels of difficulty converting between imperial (customary) and metric unit of length using unit fractions and unit cancelling. The answer keys for these worksheets show multiple steps where required to convert between the measurement system as well as between various unit scales, so they are very useful for understanding how to cancel units when solving a conversion problem.

Centimeters to Inches

8 Customary and Metric Worksheets

Converting between metric and customary unit lengths is all about converting centimeters to inches and back. These worksheets provider a solid base for the remaining sheets in this section.

Centimeters to Inches

Customary to Metric Length

12 Customary and Metric Worksheets

Unit conversion worksheets for converting customary lengths to metric/SI unit lengths.

Customary to Metric Length

Metric to Customary Length

20 Customary and Metric Worksheets

Unit conversion worksheets for converting metric/SI unit lengths (meter base units) to customary units.

Metric to Customary Length

Mixed Practice

16 Customary and Metric Worksheets

Unit conversion worksheets for converting both directions between metric/SI unit lengths and customary units.

Mixed Practice

Customary and Metric Conversion Worksheet

Once you have mastered converting between units in their own system of measurement, the next step is to learn how to convert between metric and customary units. The worksheets in this section introduce conversions between the two systems for mass, volume and distance measurements. Each of these conversions requires memorizing various constants.

cm to inches

There are exactly 2.

§ 40. Conversion of quantities to other units of measurement — «Mathematics», Zubareva I.I., Mordkovich A.G.

Select category:

All categoriesEnglish languageBiologyExtracurricular activitiesGeneral historyGeographyFor director, head teacherAdd. EducationNatural scienceFine art, Moscow Art and CinematographyForeign languagesComputer scienceHistory of RussiaTo the class teacherCorrectional educationLiteratureMathematicsMusicGerman languageLife safetySocial scienceNatural scienceReligious studiesNative literatureMother tongueRussian languageSocial teacherTechnologyUkrainian languagePhysicsPhysical educationFrench languageSchool psychologistOther

Select class:

All classes Grade 1 Grade 2 Grade 3 Grade 4 Grade 5 Grade 6

Select

textbook:

All textbooks «Mathematics», Vilenkin N.Ya., Zhokhov V.I. and others. «Mathematics», Zubareva I.I., Mordkovich A.G. «Mathematics», Merzlyak A.G., Polonsky V.B., Yakir M.S. / Ed.

Select subject:

All topicsChapter 1. Natural numbers§ 1. Decimal number system§ 2. Numeric and alphabetic expressions§ 3. The language of geometric drawings§ 4. Direct line. Line segment. Ray § 5. Comparison of segments. The length of the segment § 6. Polyline § 7. Coordinate ray § 8. Rounding natural numbers § 9. Estimating the result of an action § 10. Calculations with multi-valued numbers § 11. Rectangle § 12. Formulas § 13. Laws of arithmetic operations § 14. Equations § 15 Simplifying expressions§ 16. Mathematical language§ 17. Mathematical modelChapter 2.

Herzog Maschinenfabrik: MetalLab

- Home

- Products

- Standard Automation

- MetalLab

MetalLab in a container

Production Sample Feed Conveyors: Two parallel conveyors allow standard and high priority samples to be fed simultaneously.

Loading a production sample by a robot into the HN-FF

Checking the surface of a milled sample using an automatic vision system

Production sample on the spark bench of the optical emission spectrometer

Changing the position of the production sample on the spark bench of the optical emission spectrometer

Marking of the production sample using a dot matrix printer

MetalLab Standard Container Components

Production Sample Clamp in HN-FF

Milled Production Sample in HN-FF Transmission Position

Production Sample on Optical Emission Spectrometer Spark Stand

Production sample marking with dot matrix printer

Retrieval of a recalibration sample from the recalibration sample magazine by the robot

Screen view of the PrepMaster Entry control system

State-of-the-art solution for fully automated preparation and analysis of non-ferrous metal samples — small size, high configurability and flexibility

Use

Preparation and analysis of steel samples by milling and optical emission spectrometry or X-ray fluorescence analysis.

Materials

Non-ferrous samples up to 60 mm in diameter, round with parallel surfaces

Operating mode

Robotic automation

HERZOG’s MetalLab is the optimal solution for automated preparation and analysis of non-ferrous samples. It is possible to integrate both optical emission spectrometers and X-ray fluorescence analysis devices. Distinctive features of MetalLab are the flexible configuration of all components, adaptability to specific customer requirements and compact design. MetalLab is available as a standard laboratory or as a container version.

The operator registers samples using the registration terminal, barcode scanner, or batch registration feature in PrepMaster. Various loading options are available, including conveyors for normal and priority samples, spiral magazines or drawers for sample batches. MetalLab fits in a standard container and can be installed directly on the production site for immediate analysis.

MetalLab includes a milling machine HN-FF for preliminary and fine milling of the sample surface. As an alternative, HN-SF can be used to saw, for example, mushroom-shaped specimens and then mill the surface of the specimen. After completion of the preparation, the sample is moved to the analyzer. As an option, the automatic vision system can inspect the sample surface and identify good/bad samples as well as spark points. After analysis, the sample is moved to a magazine or container. As an option, the sample can be marked with a wax, needle or label printer.

MetalLab functions have been optimized to ensure the highest performance in analysis and the shortest sample preparation and analysis times.

MetalLab offers the following standard and optional features:

Production Sample Processing

• Priority Sample Management: The PrepMaster Entry management software allows you to easily register high priority production samples for preparation and analysis. As a result, these patterns are given preference over those with normal priority.

• Buffer magazine: The buffer magazine is a standard element of SteelLab and is used for temporary intermediate storage of loaded product samples. An intermediate buffer may be needed if several samples are registered within a short time or if processing of the current sample is delayed due to certain assay-related circumstances. The PrepMaster screen visually displays samples waiting for further processing. The number of places in the buffer store can be adapted to the requirements of each customer.

• Stores for archiving: once analysis is complete, production samples can be sorted into different drawers. PrepMaster automatically keeps track of the number of samples in the boxes and issues an alert if they are full.

Processing recalibration and control samples

• Sample configuration: PrepMaster has an extensive set of tools for configuring recalibration and control samples. Depending on the sample diameter, the operator can determine the number and spatial distribution of spark points, the sequence of sparks, the allowable time before re-milling the sample, etc.

• Sample Management: PrepMaster controls all important characteristics of recalibration and control samples, such as sample height and number of free spark positions. The sample height is measured in a milling or grinding machine and automatically transferred to the PrepMaster system. All data is easily accessible and clearly presented. In principle, the number of recalibration and control samples that can be used is unlimited and limited only by the available space.

• Control test scheduling: the operator can easily create daily, weekly or other cyclical schedules for control sample analysis. For ease of management, different control samples can be combined into groups. The result of the analysis of control samples determines the need and type of recalibration.

• Various Recalibration Strategies: PrepMaster can run both full and selective recalibrations. Selective recalibration is used if only a few channels of the instrument are outside the specified limits. A full calibration may be required if more channels are out of range or if selective recalibration fails. The operator can choose whether incoming production samples can be measured between test samples. Otherwise, the production samples will be blocked until the measuring instrument is in the correct measuring range.

• Various recalibration strategies: PrepMaster can run both full and selective recalibrations. Selective recalibration is used if only a few channels of the instrument are outside the specified limits.

Sample registration

• Connect to a layer 2 system: PrepMaster creates an interface to connect to a higher layer 2 system to obtain sample identification. PrepMaster comes with all standard interfaces commonly used in steel mills. In rare cases, when the client ID is not present in the default settings of PrepMaster, it can be installed without problems. If an interface to the Level 2 system is not required, the Sample ID can also be entered manually, read using a barcode scanner, or selected from a list created by PrepMaster.

• Various registration devices: Samples can be registered with various HMI devices such as container wall data entry terminal, registration PC or PrepMaster PC.

Worksheets

• Worksheet Creation: To have full control over all sample preparation and analysis processes, the operator can create, modify and delete worksheets for all sample types. Editing worksheets is a simple process that can be performed by any authorized operator.

• Worksheet Overview: PrepMaster provides a complete overview of all worksheets, including sample history as well as planned sample preparation and analysis steps.

Spark point detection with imaging system

As an option, a camera system for automatic spark point detection can be integrated. The operator can define criteria to include or exclude areas on the sample surface. You can also define primary and secondary areas of interest for analysis. Of course, the robot moves the samples between the individual sparks fully automatically and precisely. If the sample does not have a suitable zone for analysis, then the sample is either re-milled or removed from the machine, depending on what is set in the PrepMaster settings.